In the current fast-paced world, effective packaging solutions solutions are crucial for businesses seeking to safeguard their items during transportation and warehousing. Amongst the various options available, bubble wrap machines have emerged as a modern and efficient choice. These machines allow companies to create customized bubble wrap on demand, providing a versatile and dependable way to ensure that products remain protected from harm.

These machines streamline the packing process by creating tailored defensive cushioning that meets specific needs. By using the capability to modify the depth and size of the bubbles, businesses can pack fragile items securely, minimizing the risk of breakage and boosting customer satisfaction. With e-commerce grows to expand, the need for reliable packaging makes these machines an important expenditure for businesses seeking to improve their logistical operations.

The Way Bubble Film Machines Work

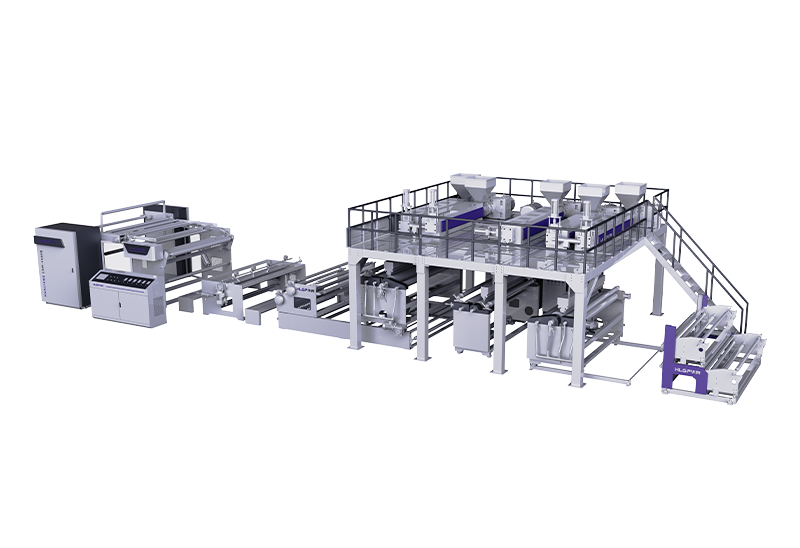

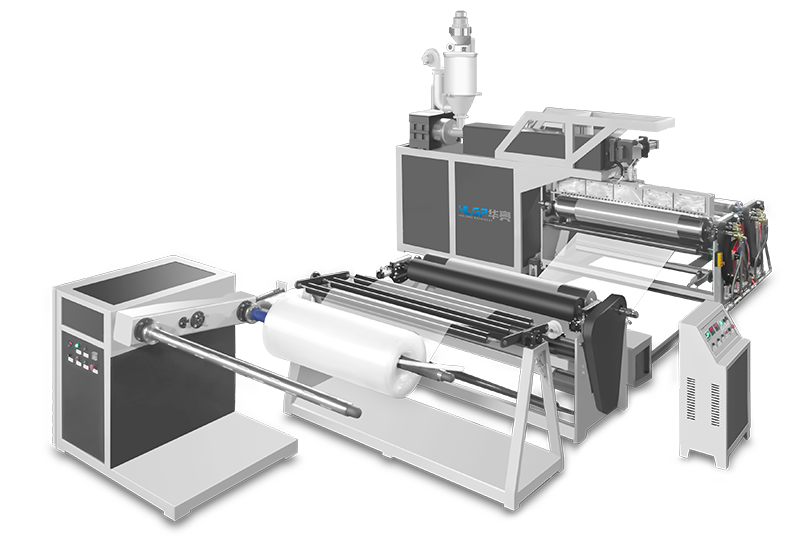

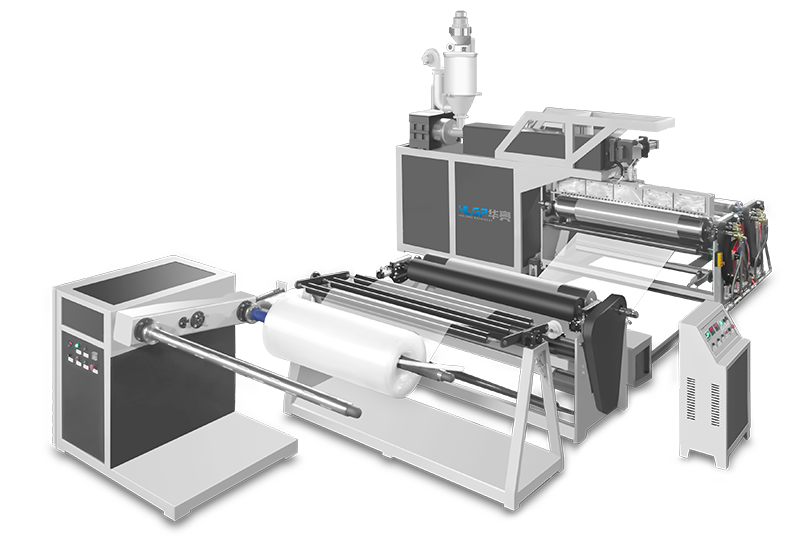

Bubble film machines are built to manufacture bubble film efficiently and in large quantities. The process starts with feeding plastic resin into the machine, where it is heated and shaped into a thin film. This film is then coated with air to create bubbles, which constitute the cushioning aspect of the bubble wrap. The ability to produce large rolls of bubble wrap allows manufacturers to meet high demand quickly.

Once the bubbles are formed, the machine continuously handles and chills the film to ensure structural integrity. The film is often layered to enhance strength and durability. After reaching the required thickness and bubble size, the film is wound up for convenient storage and distribution. This phase in the production process is vital for defining the quality of the end product.

Finally, the rolls of bubble wrap can be trimmed and formatted according to client specifications. Advanced bubble film machines may feature capabilities like automatic cutting, folding, and packaging solutions to enhance productivity. This integration of technology streamlines the process further, positioning bubble film machines a vital solution for modern packaging needs.

Benefits of Using Bubble Wrap for Shipping

Bubble wrap is famous for its safeguarding properties, making it an ideal choice for wrapping delicate goods. Its unique air-filled structure creates a protective barrier that dampens shocks and vibrations, significantly reducing the risk of harm during transportation. Hualiang (HLGP) Machinery makes bubble wrap especially critical for transporting fragile products, such as pottery, electronics, and clay products. Enterprises that prioritize the protection of their merchandise can rely on bubble wrap to ensure their products arrive at their endpoint in untouched form.

Additionally perk of bubble film is its light nature. In contrast to traditional packaging materials, such as foam, bubble film provides a high level of protection without increasing unnecessary weight to the shipping materials. This feature is particularly useful for businesses looking to lower freight expenses. By using bubble wrap, businesses can achieve financial advantages on shipping fees while still upholding the quality of their goods throughout the delivery journey.

Furthermore, bubble wrap is adaptable and easy to use. It can be customized to fit different shapes and sizes, allowing for a flexible packaging solution that meets varied business needs. Whether wrapping individual items or padding voids in larger packages, bubble film adapts smoothly to various packaging needs. Furthermore, its ability to be repurposed enhances its attractiveness as an eco-friendly option, catering to consumers increasingly worried about sustainability in their shopping behaviors.

Determining the Right Bubble Film Machine

When picking a bubble film machine, it is important to take into account the output capacity required for your particular needs. Multiple machines offer different output rates, so you should evaluate the volume of bubble film you expect needing on a daily basis. A greater output machine may be needed for bigger operations, while smaller businesses might find that a more compact model suffices. Considering the scale of your packaging requirements will help guide you to an appropriate choice.

Another key factor is the machine's flexibility in producing multiple types of bubble film. Some machines can produce various bubble sizes, thicknesses, and even bespoke features for packaging particular items. If your business requires multiple packaging solutions, investing in a bubble film machine that offers this flexibility could enhance your overall efficiency. Seek out models that allow straightforward adjustments and have the capability to produce a selection of bubble film options.

Lastly, consider the ease of operation and maintenance of the bubble film machine. User-friendly controls and clear instructions can significantly reduce the learning curve for your team. Additionally, exploring the accessibility of support services and replacement parts can help ensure that your machinery remains functional with minimal downtime. Selecting a machine that combines reliability, efficiency, and ease of use is vital for guaranteeing your packaging process functions effectively.